Two stage oil filter

Operating instructions of touch screen

1、 After the power is turned on, the touch screen will display the equipment model, manufacturer, instructions, and

The operation page, the lower right corner is the next page, time, and the manufacturer's website.

2、 The control system is divided into manual control and automatic control, inching operation and entering the operation page.

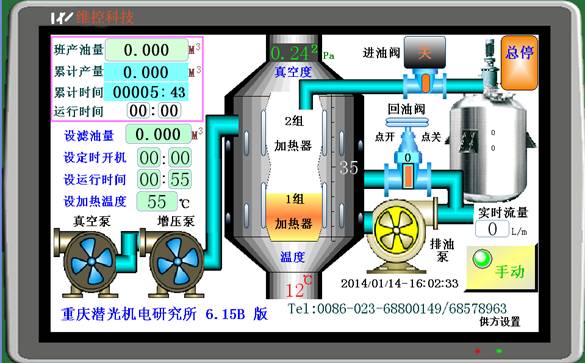

1. Automatically display at runtime:

Real time flow () liter/shift production flow () m ³

Cumulative production () m ³

Running time () Cumulative running time ()

2. Operation parameter setting: the following parameters can be set only after the parameters set in the Institute have been set during automatic control.

(1) Scheduled startup time: set the daily scheduled startup time when necessary.

(2) Operation time: refers to the single operation time, with the setting range of 3 minutes to 99 hours.

(3) Set heating temperature: set the temperature of heating oil according to oil filtering requirements.

Set heating temperature: jog the number behind the set heating temperature, enter the modification page, select the required temperature number, enter it, jog to confirm, confirm again, and the temperature modification is completed, and the recommended temperature value is between 35C º - 60C º. If two groups of heaters are needed, jog the Ω indicator lights of the two groups of heaters to light up, and then jog the lights off to cancel. Stop the machine and jog the "total stop".

Timed startup operation:

(1) . Setting: regular startup time and running time.

(2) When inching is set, the "Ω" indicator light after the startup time is on, and the operation is automatic when the set time is reached.

(3) Click the "Ω" indicator light to turn off, and the startup is cancelled when the setting time is set.

(4) . Stop the machine by inching "total stop", or it will stop automatically when it reaches the running time.

3. Automatic and manual conversion: (jog the automatic key to change to manual operation; jog the manual key again to change to automatic operation)

4. Manual control operation: when manually controlled, each operation step does not affect each other to start and stop separately.

(1) Start the vacuum pump. When the vacuum reaches the limit, start the booster pump.

(2) . Feed oil slowly. Open the oil inlet valve at a certain point, and then gradually open the large oil inlet valve; Click the oil inlet valve to close it gradually.

(3) When the liquid level reaches (20), open the oil outlet valve and oil return valve and start the oil drain pump.

(4) Start the heater.

(5) The liquid level control has the opening control of oil return valve and oil inlet valve.

Start the pump by inching, start the pump and heater by inching once, and stop by inching again. When the heater is started, one or two groups of heaters can be inched as required.

Oil inlet valve: it can be opened or closed by clicking, which means the valve is closed and opened by clicking.

(6) The shutdown operation is the reverse operation of the startup program. That is,

The manual shutdown procedure is:

Stop heating first, close the oil inlet valve, close the oil drain pump after the oil level drops to 20, then close the oil outlet valve, stop the booster pump, and stop the vacuum pump.

In case of emergency stop, press "general stop".

5. Automatic control: jog the manual key to enter automatic operation. Note that before automatic operation, manually control the oil level and eliminate oil foam before automatic operation. The flow of oil inlet and outlet is related to the opening of oil return valve. The opening of the oil return valve is large and the oil output is small. The opening of the oil return valve is small and the oil output is large.

When the liquid level is 20 after the parameter is set, you can click the manual key to enter the automatic operation state: after the vacuum reaches the value, the booster pump starts and feeds oil, and after reaching the starting liquid level of the oil pump, the oil pump starts to drain oil. During operation, the electric valve will automatically adjust according to the liquid level, and during operation, the flow and oil level can be observed on the display screen.

Contents displayed on the touch screen: temperature, vacuum, oil level, inlet valve opening, instantaneous flow, cumulative flow, single operation time, cumulative operation time, etc.